Products

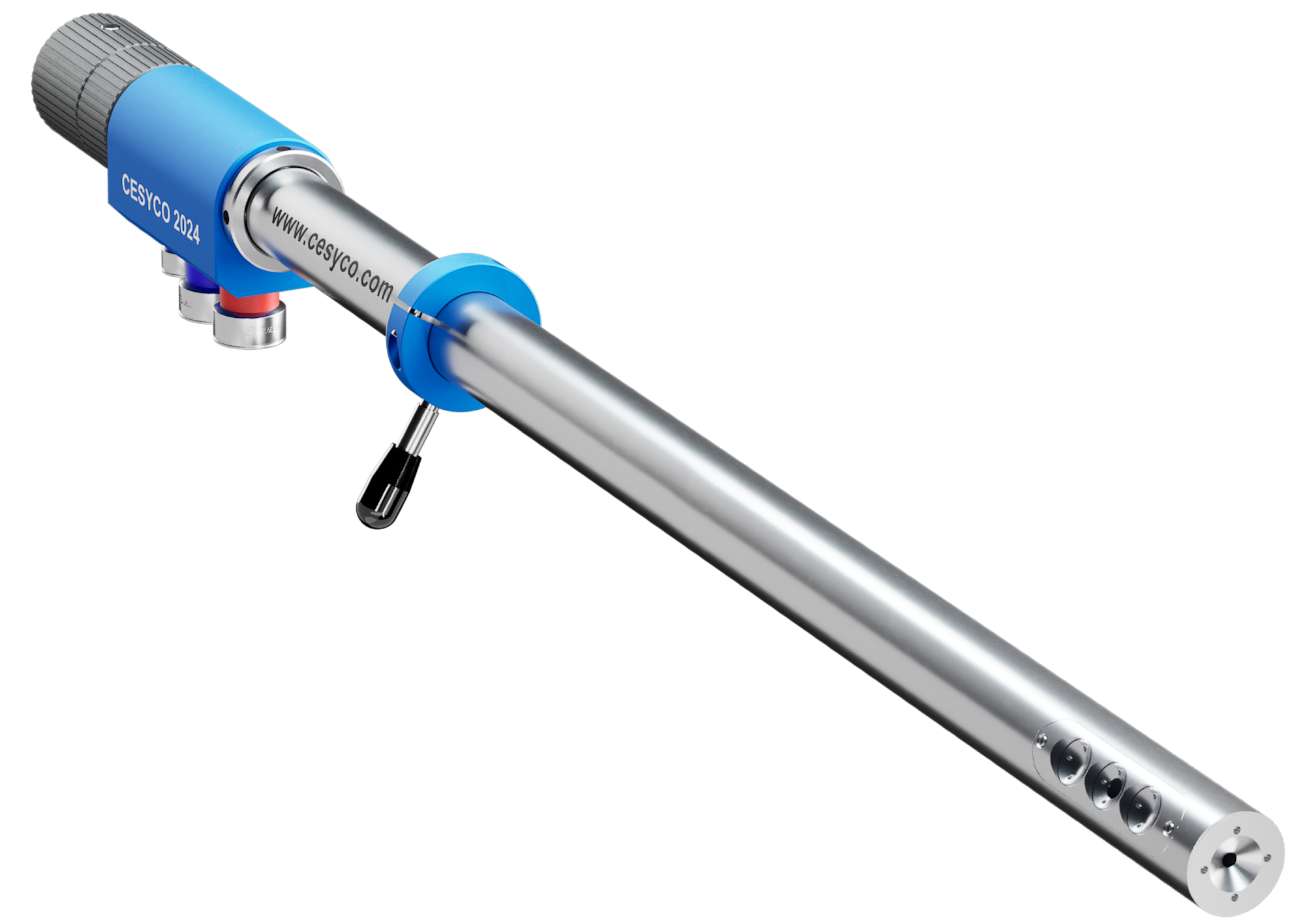

Tailor-made solutions for high-temperature inspections. Discover our range of fixed and portable endoscopes, designed to deliver high-quality images even in the most extreme environments. Robustness, precision and reliability for your industry.

Endoscopes

- Distribute temperature throughout the sheath

- Eliminates hot spots responsible for weld failure

- Increase sheath life

Thanks to a rotation key, you can turn the sheath on itself, offering a complete vision configuration.

- Dual vision: see the sides and front of the oven at the same time.

- Multiple angles available: camera heads oriented at 20°, 45° and 65°.

- Led lighting

Technology

Equipments

Safety station

Control box

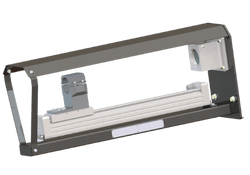

Extractor bench

Electrical cabinet

Service

In the most demanding industrial environments, every detail counts. That’s why CESYCO puts its expertise and high-performance equipment at your disposal to carry out high-temperature visual inspections, right on your site.

Thanks to our specialized endoscopes, we capture high-quality images of the inside of your facilities, enabling you to monitor wear, detect anomalies and optimize maintenance, all without production downtime.

Contact

We analyze your specific needs and propose a tailor-made solution. This stage includes the precise targeting of your request and the drawing up of an appropriate quotation.

Intervention

Our technicians come directly to your site, equipped with state-of-the-art equipment. They carry out inspections in complete safety, even in the most demanding environments.

Images delivery

At the end of the inspection, we provide you with the high-quality images captured during the inspection. These visual aids, in photo or video format, are ready to be used according to your needs.

- Check the state of internal wear on an operating furnace.

- Anticipate and plan maintenance operations.

- Monitor a hot process in real time.

- Detect malfunctions without stopping production.

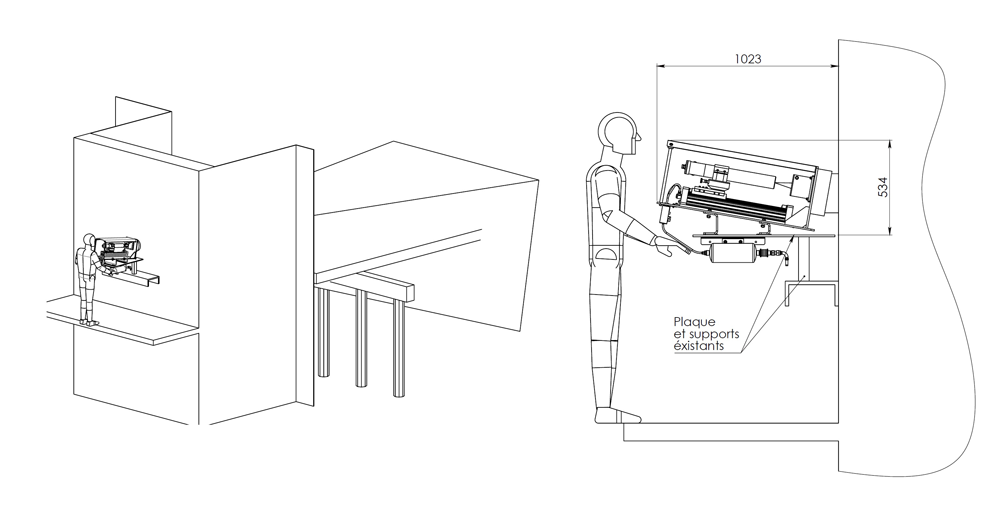

3D Simulation

3D vision simulation

Targeted solutions: our engineering department is able to design a virtual projection of the endoscope's field of vision in the furnace, to ensure that it is correctly positioned.