Good maintenance starts with good habits.

Used in extreme environments, a high-temperature endoscope is a highly technical piece of equipment. Its robustness is an asset, but it remains a precision piece of equipment that must be handled with care to guarantee reliable inspections over time. This guide will help you adopt the right gestures right away.

Handling: attention to everyday gestures

Your endoscope can withstand temperatures of up to 2000°C, but a simple, misplaced shock can be enough to damage it.

Absolutely avoid dropping the device or hitting the inspection head: internal lenses, electronic components and Stäubli-type connectors (water/air) are sensitive areas.

A few simple reflexes:

Check the condition of fluids

Never use the endoscope without checking the condition of your fluids (water/air), their cleanliness, and above all the flow rate: insufficient flow leads to a gradual rise in temperature, difficult to detect with the naked eye.

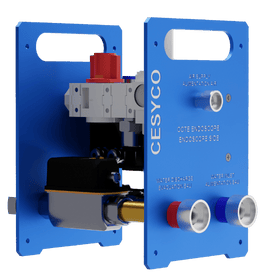

Using a control station

Control stations allow you to monitor these parameters in real time, thanks to a thermometer, flowmeter and built-in alarms.

Check pipes

Avoid tangled cables, knots or areas trapped under objects: these can block the flow of air or water, or cause a drop in flow that can be fatal to the endoscope.

And, of course, always remember to return the endoscope to its flightcase as soon as the inspection is complete.

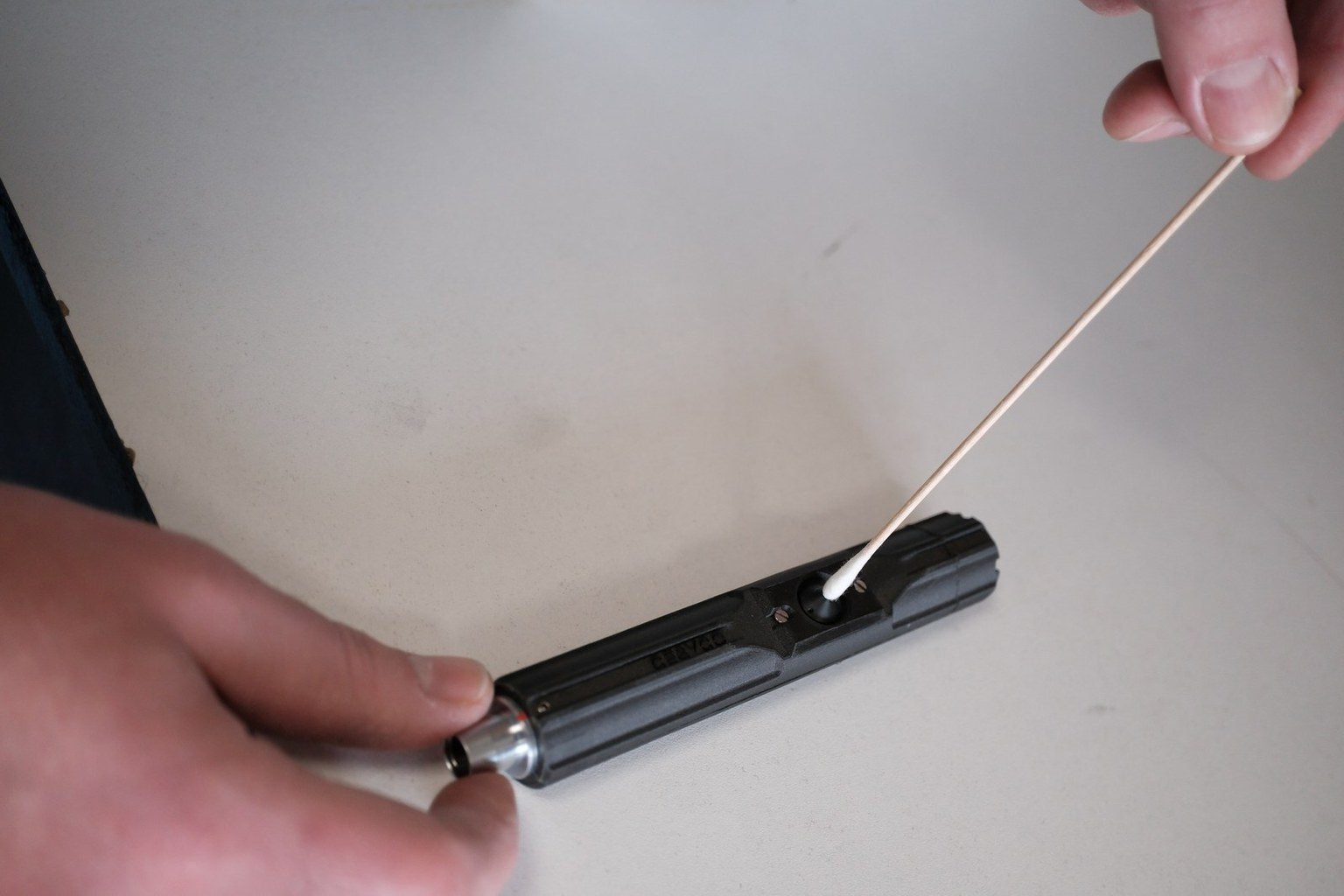

Regular cleaning: simple but essential

Systematic cleaning significantly prolongs image quality and lens life. This simple gesture is all too often neglected.

- Clean the camera head (digital endoscope) or lens (optical endoscope) after every use, even brief ones.

- Use only a clean microfiber cloth or cotton swab soaked in alcohol (or optical acetone if necessary). The onyx used for Cesyco heads is perfectly resistant to this.

- Clean only the outer surface. Never open camera heads: they are sealed in the workshop.

- If you disassemble an optical lens, take care to keep the order of the lenses. A simple reversal will alter image sharpness.

Five mistakes to avoid

Certain bad practices can have immediate consequences or delay deterioration without you even realizing it.

Handle equipment without gloves or with dirty or greasy gloves.

Wipe lenses with a fluffy cloth or tissue paper.

Forget to purge the water after use: an essential step to avoid mold, corrosion and lime deposits.

To do this, connect the air inlet to the water inlet and let the water drain out via the outlet.

Forcing on fixed parts (especially sealed heads).

When changing camera heads, loosen the two guide screws without removing them completely: they are small and easy to lose.

Before and after: the things that count

Maintenance doesn’t stop when the inspection is complete. A simple routine can help you avoid costly breakdowns.

Before use :

- Check the video display.

- Check temperature and fluid flow.

- Visually inspect head, cables and connectors.

After use :

- Completely purge the cooling system.

- Wipe down if necessary, and immediately store the equipment in its original

- flightcase to protect it from shock, dust or moisture.

Conclusion

Extending the life of your endoscope requires neither complex expertise nor additional investment: just simple, regular gestures and attention to detail.

Every check, every cleaning, every good reflex contributes to maintaining the performance of your equipment over time – and avoiding sometimes irreversible breakdowns.

By following these recommendations, you not only limit the risk of premature wear and tear, but also guarantee reliable, safe inspections that meet the requirements of your industrial environments.