In industrial sectors such as the steel, glass and cement industries, furnaces play a central role in production. However, these installations often operate 24/7, making any production stoppage costly and difficult to plan. Hot repairs are therefore an essential solution for maintaining continuity of operations while keeping costs down. In this context, CESYCO’s industrial endoscopes stand out as indispensable tools for guaranteeing safe and efficient interventions.

The challenge of hot repairs

Hot repairs present unique challenges requiring specialized tools and techniques. Key issues include

Preserving continuity of operations: Stopping a furnace in production can lead to financial losses and significant delays. Hot repairs help avoid such interruptions.

Reduce costs associated with prolonged interruptions: Minimizing downtime considerably reduces the impact on profitability.

Maintain optimum production conditions: Targeted repairs prevent deterioration in performance, ensuring constant output.

CESYCO endoscopy solutions

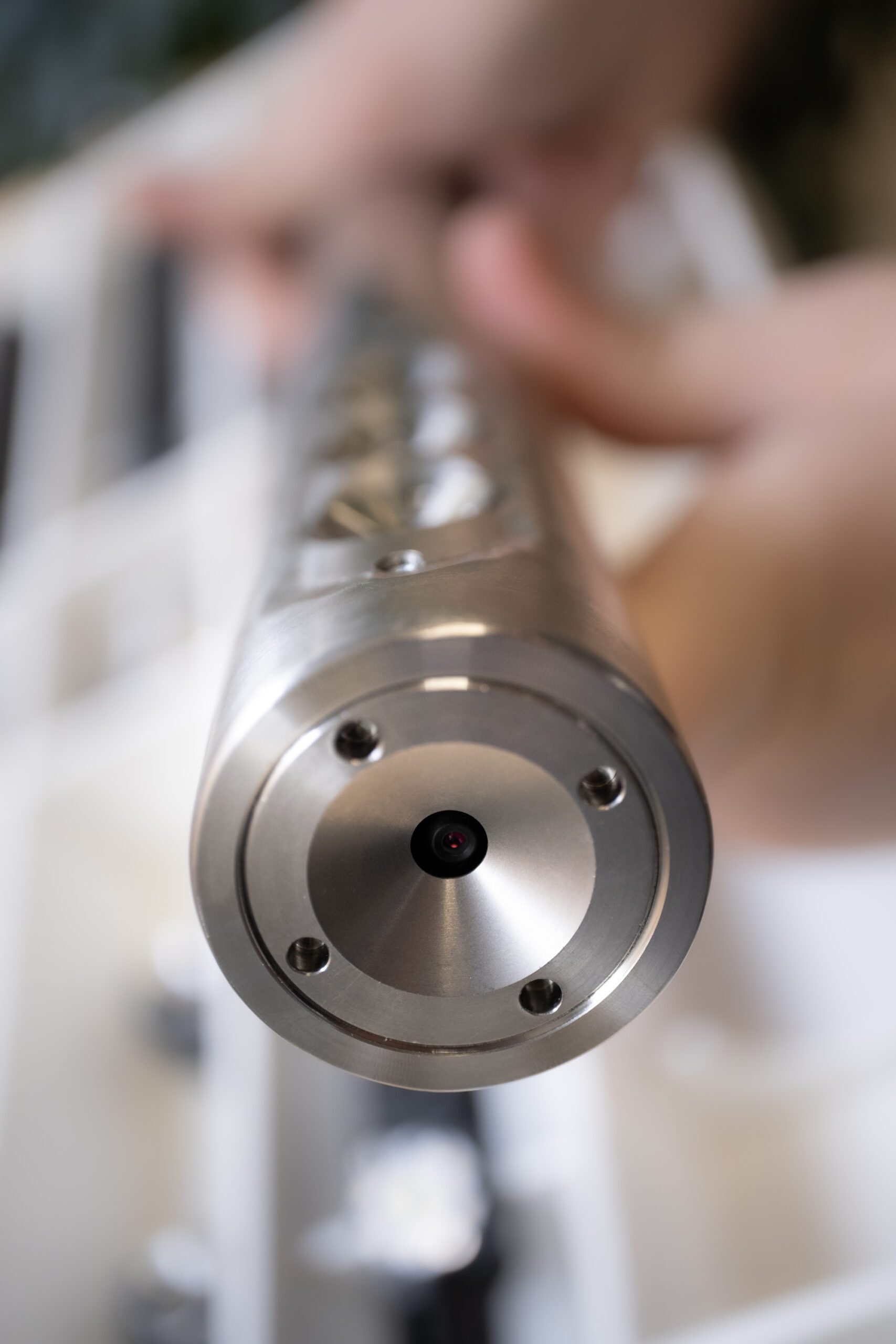

CESYCO’s industrial endoscopes offer solutions for demanding thermal environments:

Portable endoscopes with LEDs: Ideal for exploring dark and narrow areas, while providing high-resolution images in real time.

Exceptional thermal resistance: Designed for inspections in temperatures up to 2000°C, guaranteeing long-term reliability.

Real-time diagnostics: Operators can identify and assess problems immediately, without having to shut down the plant.

These tools enable accurate, fast and safe inspections, while minimizing interruptions to critical processes.

Practical example: gunning

Gunning, or reinjection of refractory concrete, is a common repair procedure in industrial furnaces. This process, crucial for prolonging refractory life, is facilitated by CYSECO’s industrial endoscopes.

Pre-inspection: The endoscopes precisely identify damaged areas, enabling targeted intervention.

Real-time control: During gunning, operators can monitor the application of concrete to ensure uniform and efficient repair.

Risk reduction: The use of endoscopes minimizes operator exposure to hazardous environments.

Sectors dependent on industrial endoscopy :

Verrerie

Inspection of glass furnaces to monitor melting of raw materials and detect refractory wear.

Sidérurgie et métallurgie

Control of burners and slab furnaces to ensure homogeneous production.

Énergie

Diagnostics of boilers and incinerators to identify obstructions and maintain thermal efficiency.

Cimenterie

Verification of rotary kilns to prevent blockages and optimize combustion.

Pour conclure :

Hot repairs are a necessity for many industries where business continuity is critical. With its innovative industrial endoscopes, CESYCO offers the right solutions to ensure precise, safe and cost-effective interventions. These tools not only extend equipment life, but also optimize performance and reduce operational costs.

Investing in tools like those offered by CESYCO means choosing reliability and efficiency to meet the challenges of the most demanding industrial environments.