Thermal power plants, whether coal, fuel oil or biomass, play a key role in global energy production. However, these complex facilities must be operated continuously to ensure optimum efficiency. High temperature inspections, performed with specialized tools such as industrial endoscopes, have become essential to ensure their energy efficiency and operational safety.

Explosions of nitrous oxide cylinders are a recurring problem at waste-to-energy plants. Up to 45 detonations a day can occur inside incinerators, generating thermal and mechanical shocks that weaken the infrastructure. These explosions cause cracks to form in refractory walls, burners to deteriorate and, in some cases, fires to break out.

This damage has a direct impact on plant operations. Prolonged shutdowns required for repairs impact on continuity of operations and site profitability. In France, these interruptions have accounted for losses of between 15 and 20 million euros over the past three years.

Fault prevention:

By identifying anomalies early, it reduces the risk of costly shutdowns.

Increased security:

It limits the exposure of operators to hazardous environments.

Maintenance optimization:

Predictive approach to plan repairs before critical stage.

Operational efficiency:

Processes monitored in real time without interrupting production.

The challenges of thermal environments

Equipment in thermal power plants, such as boilers, heat exchangers and combustion chambers, is exposed to extreme conditions:

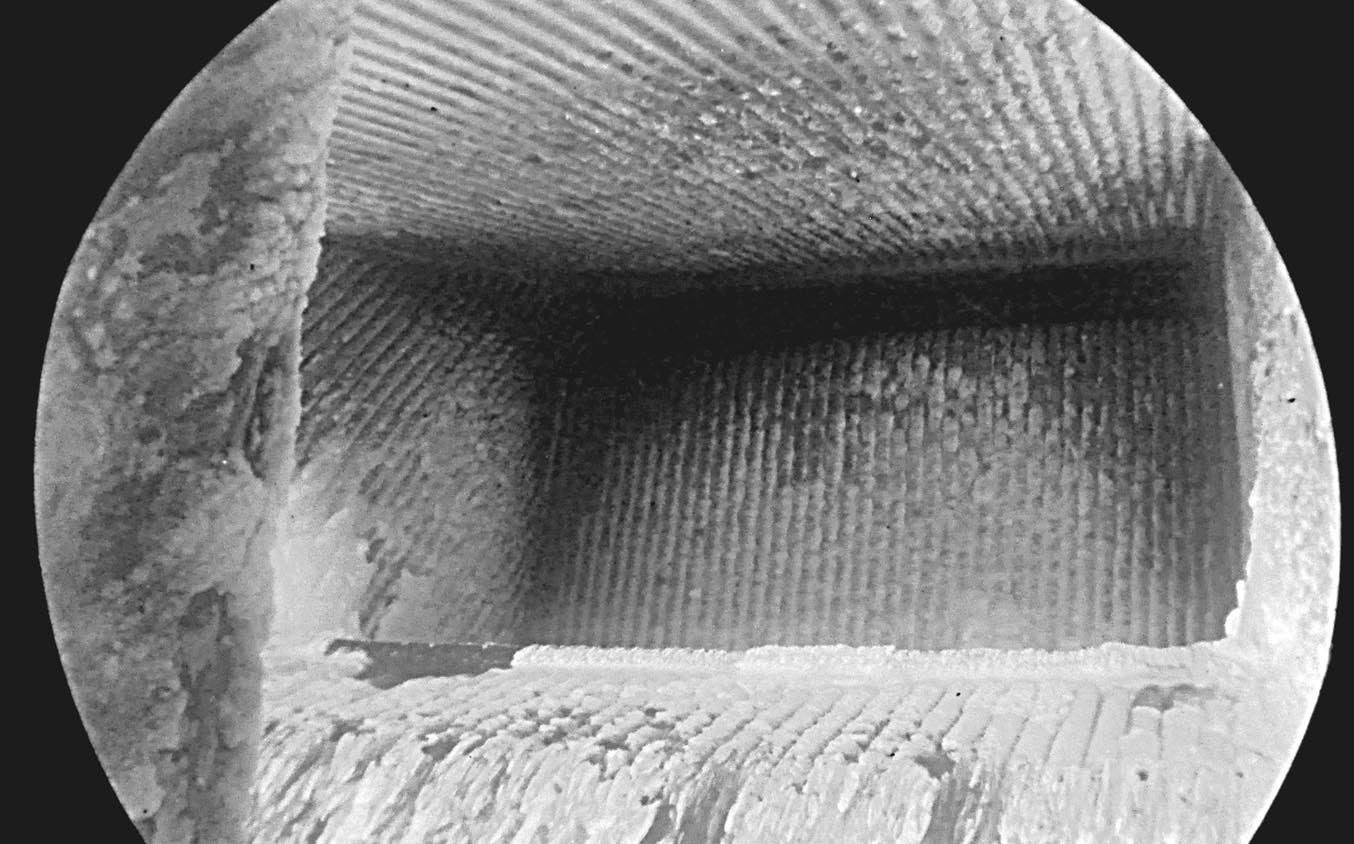

Accumulation of deposits: Soot, dust and combustion residues accumulate over time, clogging ducts and reducing energy efficiency.

Intense heat: Temperatures often above 1000°C require robust and reliable tools.

Difficult access: Some spaces, such as inside boiler tubes or dark areas, are inaccessible without appropriate technology.

High temperature inspection addresses these challenges by quickly locating obstructions and verifying the structural integrity of equipment without stopping processes.

CESYCO endoscopy solutions

CESYCO industrial endoscopes offer solutions for demanding thermal environments:

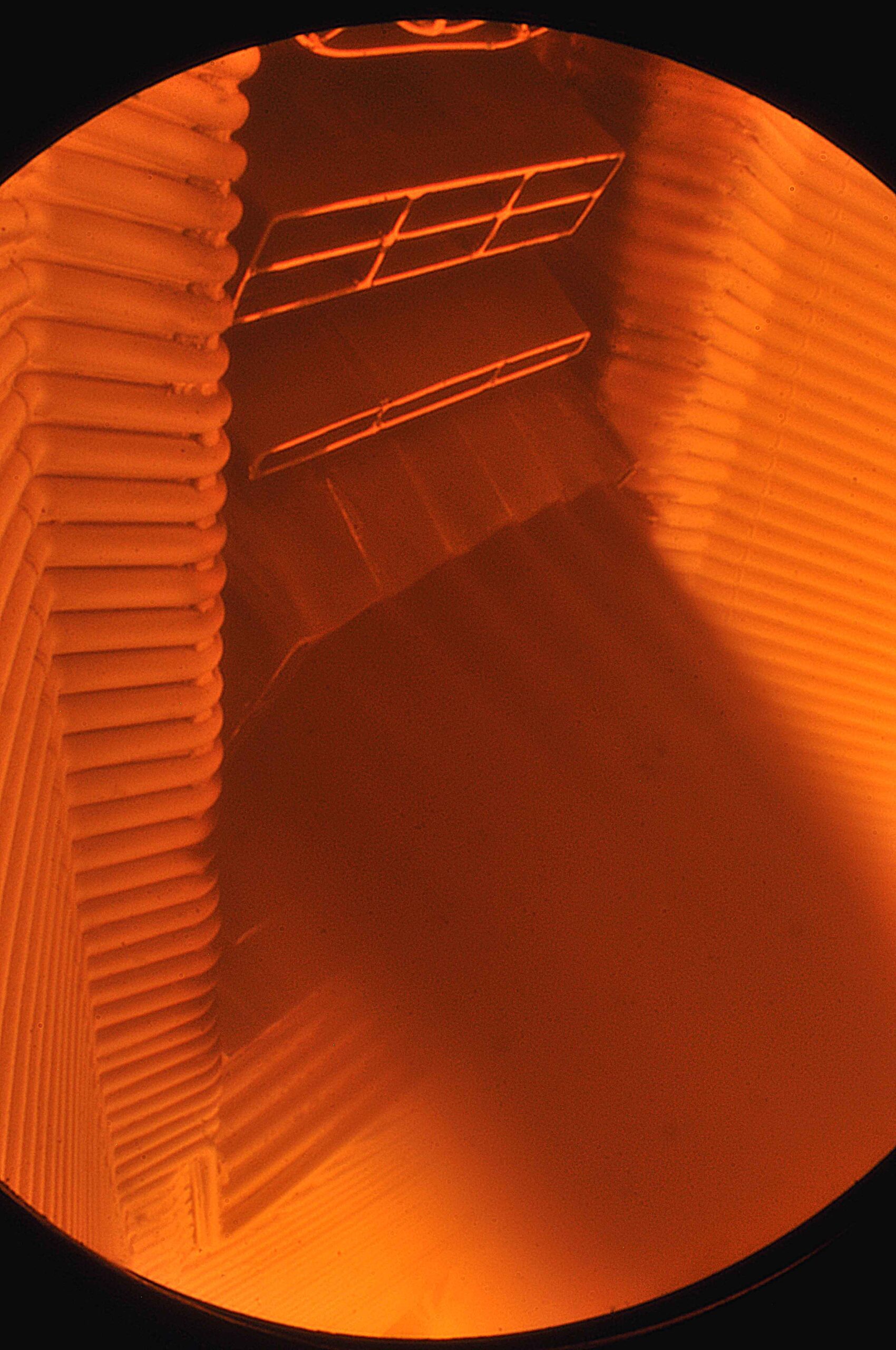

Portable endoscopes with LEDs: Ideal for exploring dark and narrow areas, while providing high-resolution images in real time.

Exceptional thermal resistance: Designed for inspections in temperatures up to 2000°C, ensuring long-term reliability.

Real-time diagnostics: Operators can identify and evaluate problems immediately, without requiring plant shutdown.

These tools enable accurate, fast and secure inspections while minimizing interruptions to critical processes.

Benefits for operators

The use of industrial endoscopes in thermal power plants offers many strategic advantages:

Prevention of unplanned outages: Anomalies such as cracks or obstructions are detected before they cause major failures.

Reduced energy loss: Rapid identification of deposits and obstructions helps optimize heat flow and reduce energy waste.

Extended equipment life: Regular and proactive inspections limit wear and prolong the performance of boilers and heat exchangers.

Improved safety: Remote inspections reduce the risk to operators by minimizing their exposure to hazardous environments.

sectors dependent on industrial endoscopy :

Verrerie

Inspection of glass furnaces to monitor the melting of raw materials and detect wear of refractories.

Sidérurgie et métallurgie

Control of burners and slab furnaces to ensure homogeneous production.

Énergie

Diagnostics of boilers and incinerators to identify obstructions and maintain thermal efficiency.

Cimenterie

Verification of rotary kilns to prevent blockages and optimize combustion.

Pour conclure :

In thermal power plants, where equipment reliability and energy efficiency are paramount, industrial endoscopy is an essential technology. CESYCO endoscopy solutions enable operators to monitor and optimize their facilities, while reducing the costs of failures and corrective maintenance.

Investing in these specialized tools means ensuring efficient, sustainable and safe energy production, even in the most demanding environments.