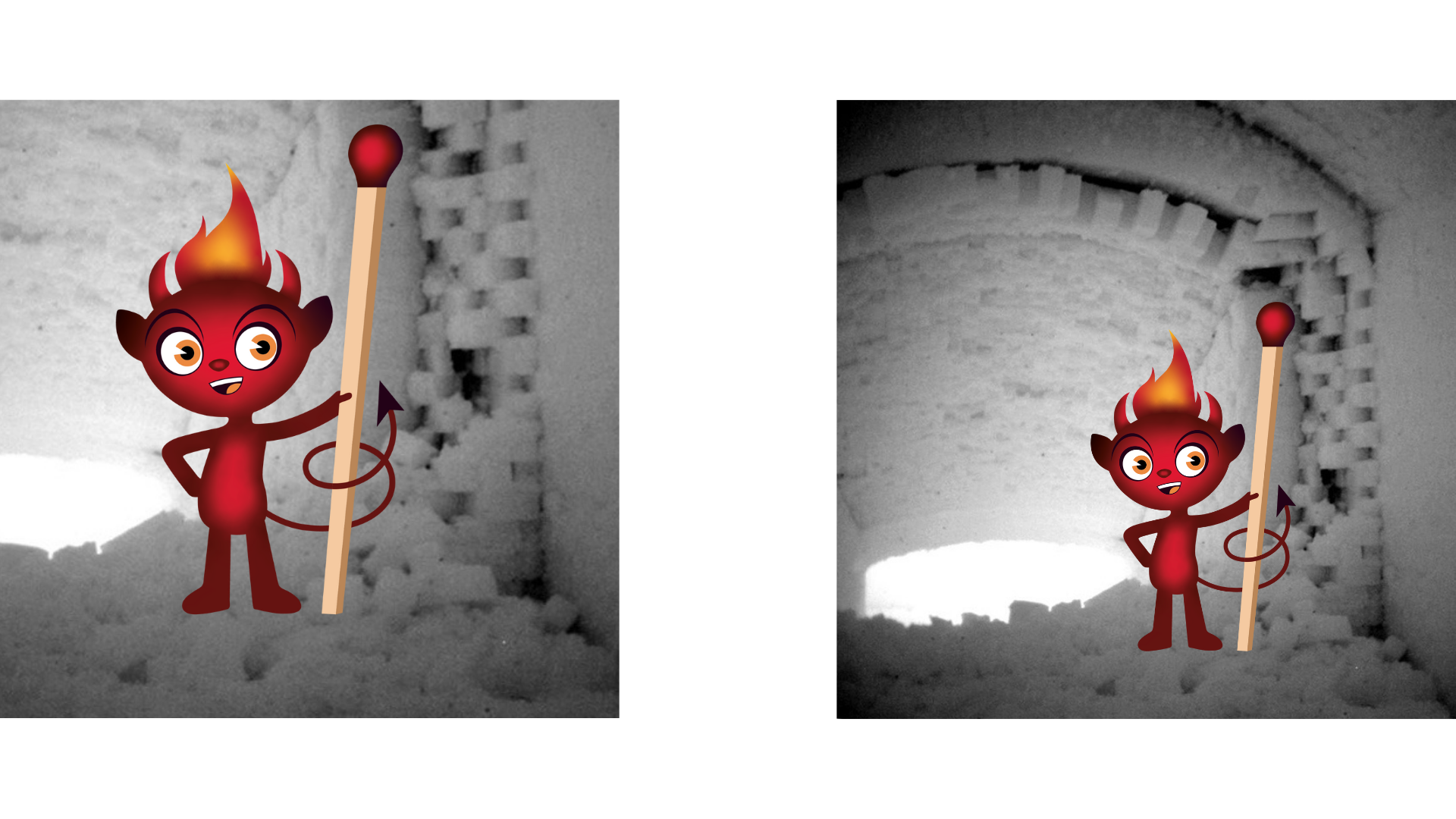

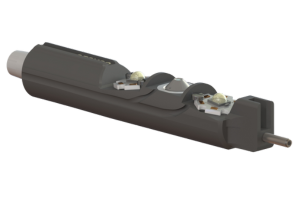

In a high-temperature industrial environment, the quality of vision is a decisive factor in carrying out reliable and safe inspections. At CESYCO, this performance is based on interchangeable camera heads, designed specifically to meet each customer’s requirements. Custom-built from onyx – a nylon-based technical composite reinforced with carbon microparticles – these heads ensure optimum optical precision, while withstanding ambient temperatures of up to 60°C. Thanks to a rigorous selection of angles, fields and directions of vision, our endoscopes can adapt to the most complex situations, even in confined, dark environments or those subject to extreme stress.Industrial endoscopic vision: understanding angles, fields, directions and lighting

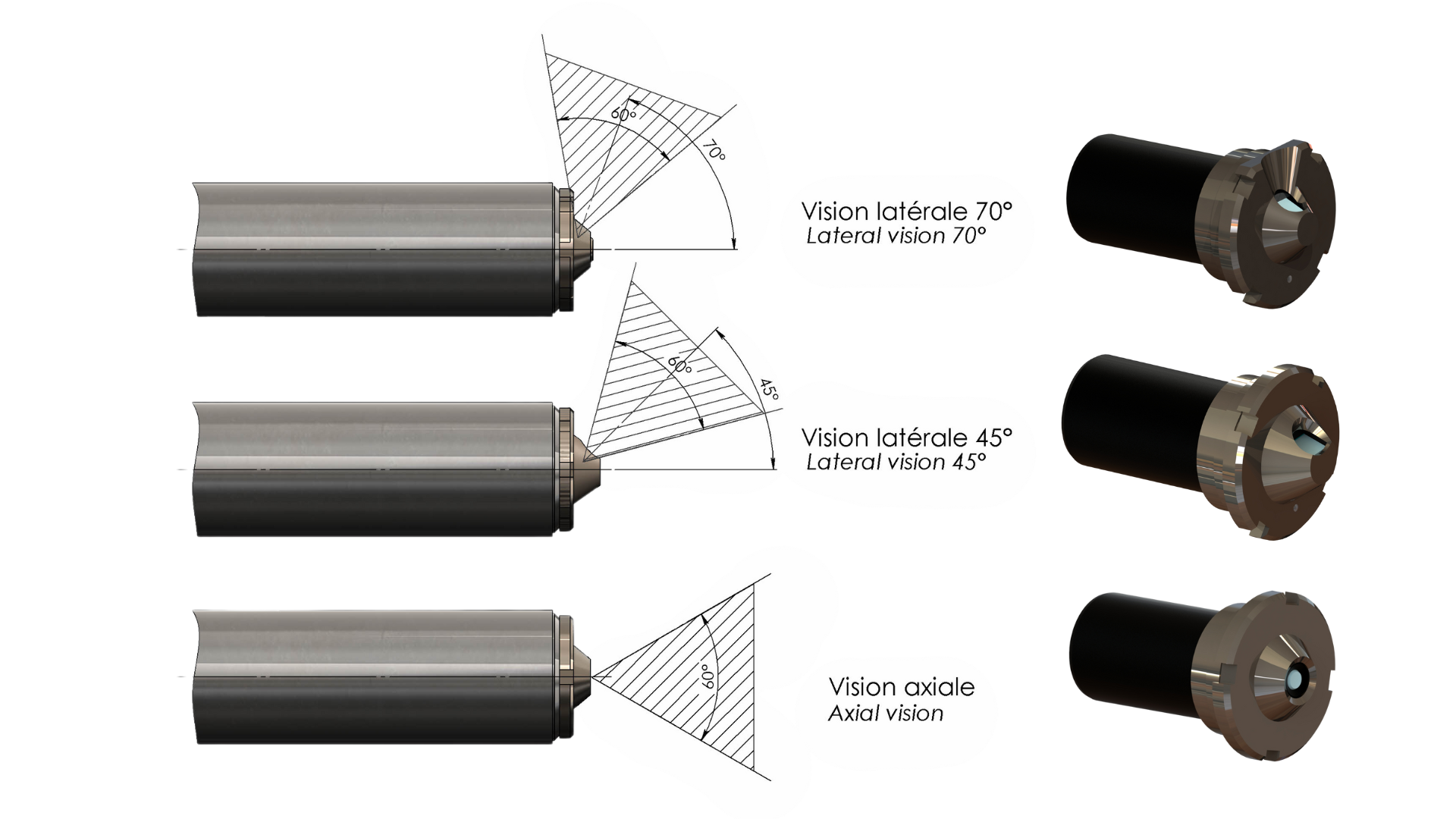

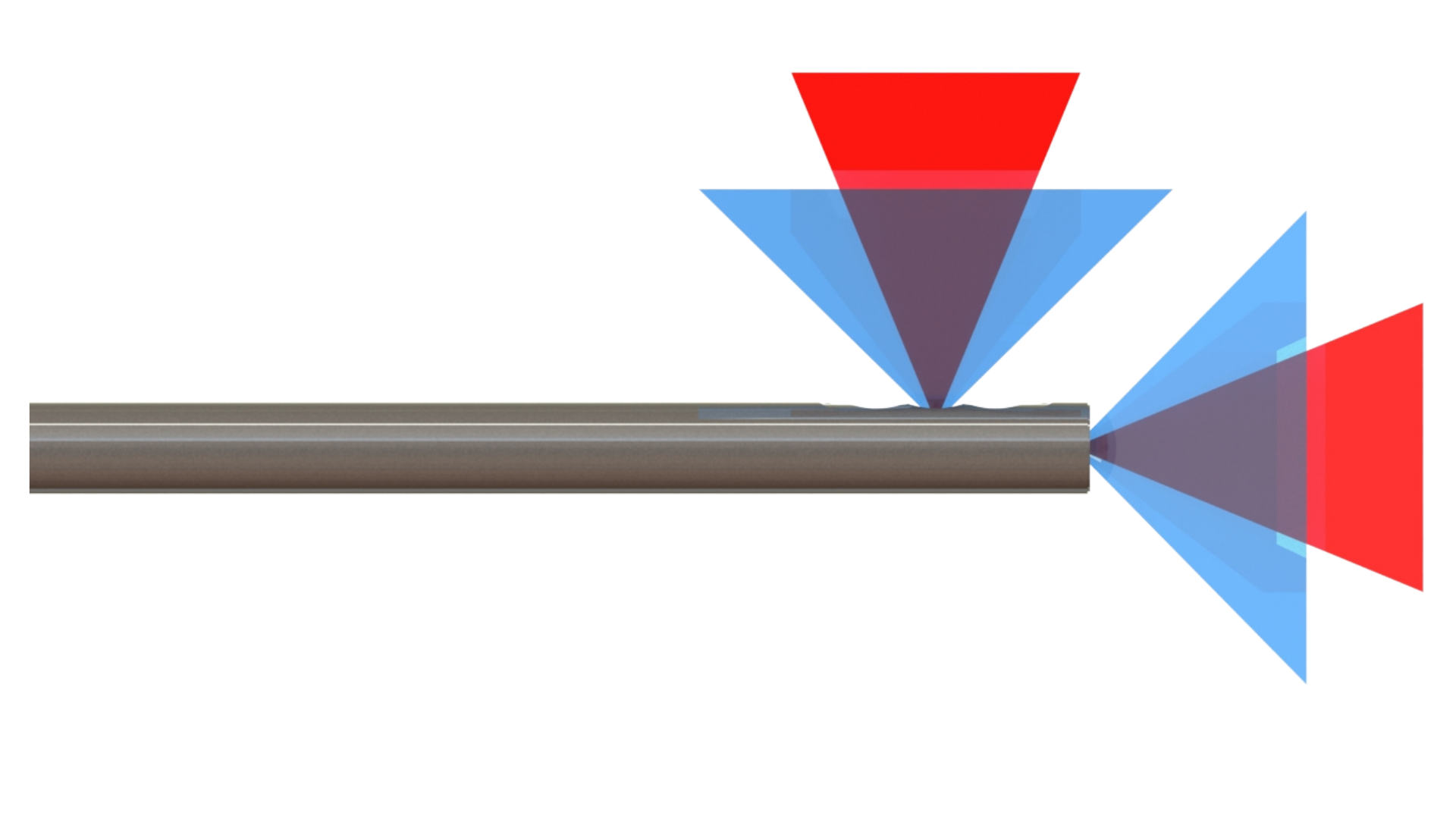

Vision directions – Axially, laterally or bi-vision?

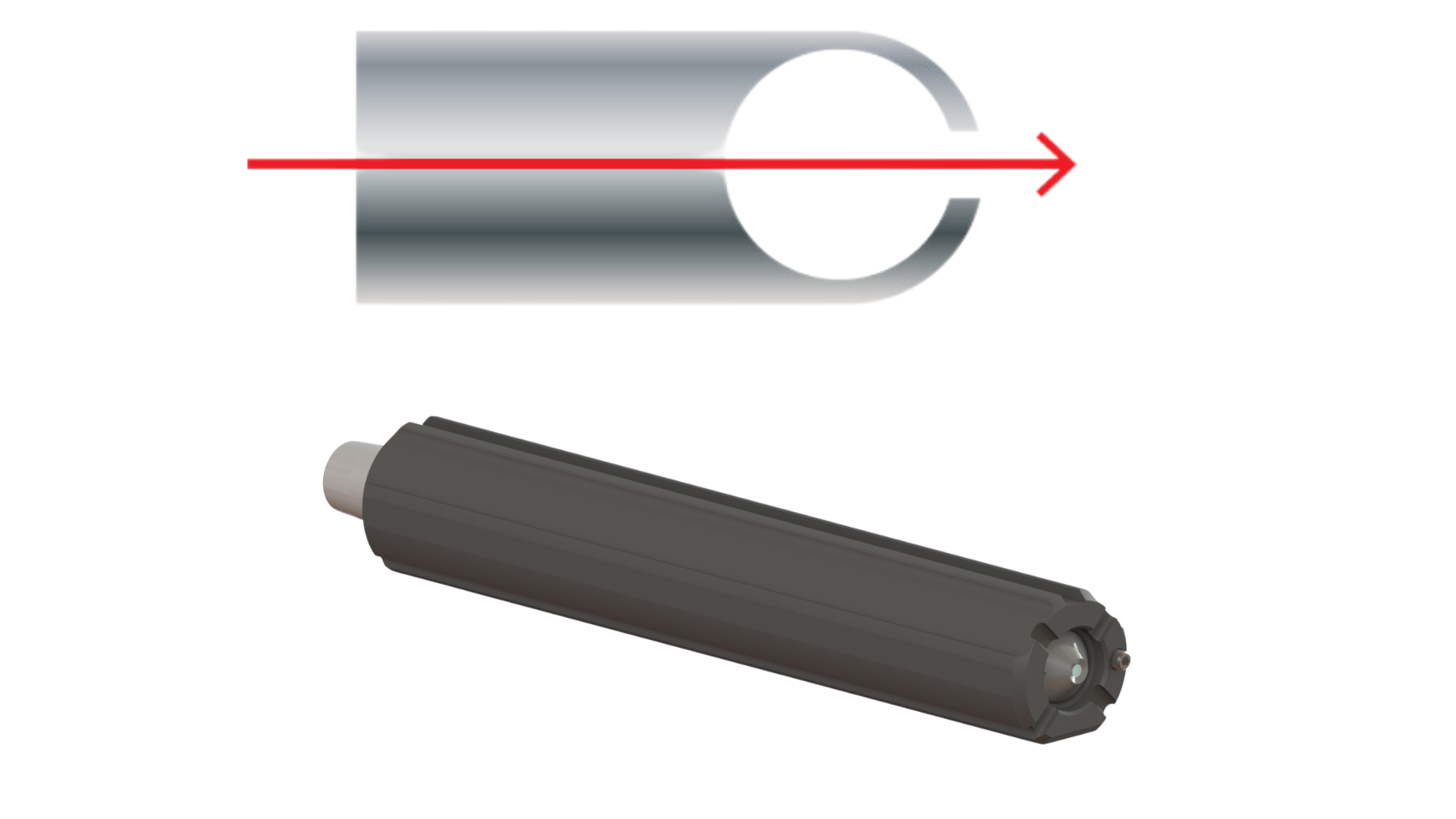

Axial view (0°): Direct observation of what’s in front of the endoscope. Ideal for inspections of deep cavities or straight channels.

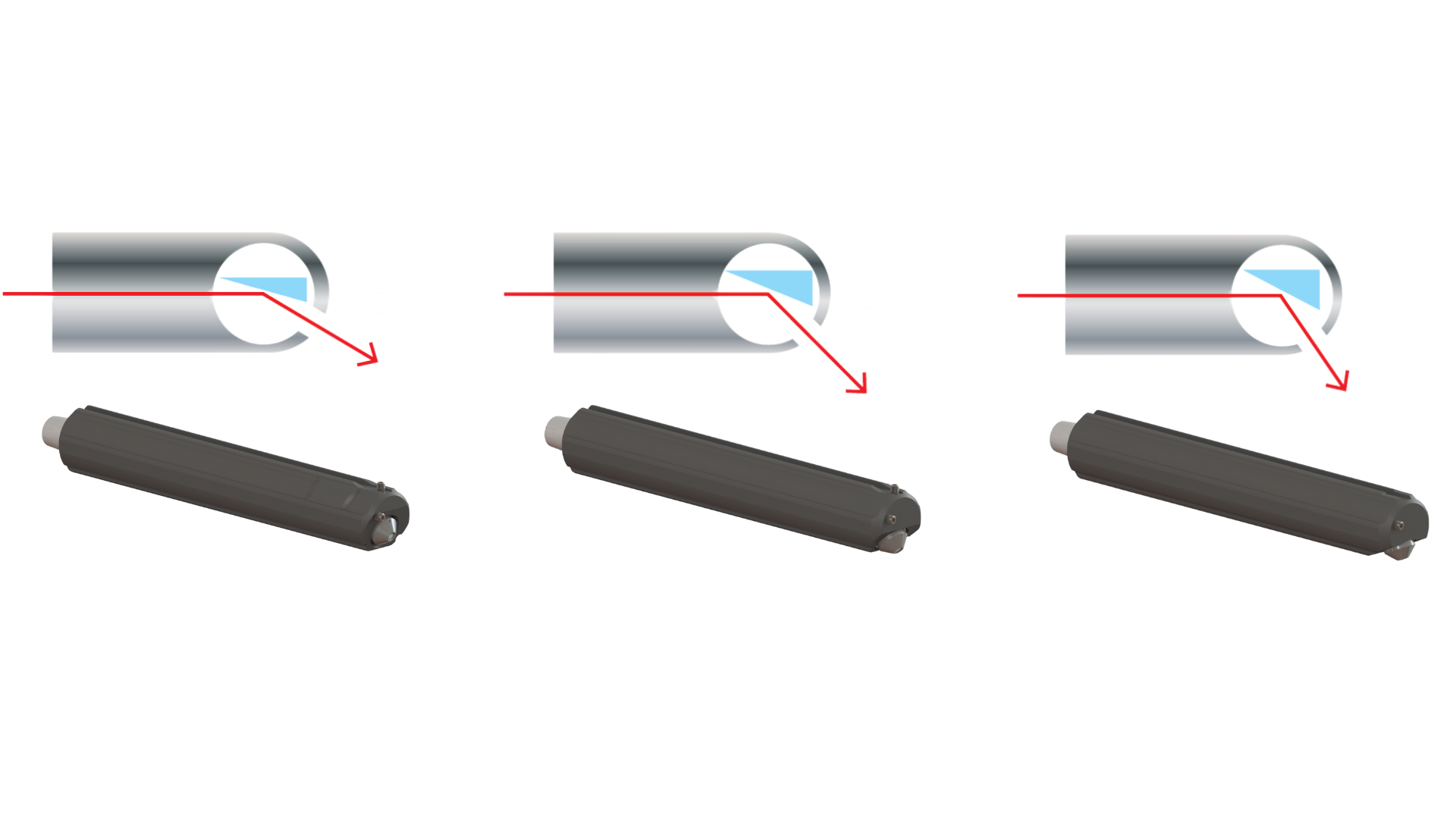

Side vision (90°): Observe walls or side areas without tilting the device. Perfect for wall or internal surface inspections.

Bi-vision: Allows simultaneous axial (0°) and lateral (90°) observation, for a complete view of the oven interior and walls. Capture photos and videos from multiple angles effortlessly, for more precise and efficient inspection.

Angles of vision – For the right perspective

Viewing angles direct the endoscope’s gaze in the desired direction, without the need to move the device:

- 0° (axial): Straight, direct vision.

20°, 45°, 65°, 90°: Adapt to complex geometries.

110°: Used for extremely offset or panoramic views.

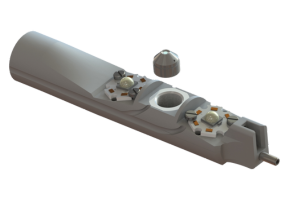

Digital camera heads

20°, 45°, 65 °

Optical lenses

Field of vision – Width or precision?

- 60°: Narrower, but deeper field of view. Ideal for targeted vision, useful for detecting precise defects or inspecting a strategic point.

- 90°: Wider field of view, enabling coverage of a large area in a single shot. Recommended for global surface checks or large-area surveillance.

LED lighting – See clearly, even in the dark

- Axial LED: Illumination in the line of vision, essential for inspecting deep areas.

- Lateral LED: Illuminates walls or off-center areas.

- Optimized visibility: LEDs reduce shadows, increase contrast and ensure a sharp image, even in very low light conditions.

Conclusion :

The performance of an industrial endoscope depends not only on its resistance to high temperatures or its image transmission technology: it also depends, crucially, on its ability to see what’s needed, where it’s needed. At CESYCO, we have made vision a strategic development focus, designing custom camera heads optimized for every inspection situation. Thanks to precise control of angles, fields of view, optical directions and lighting, our solutions adapt to the constraints of each environment, whether monitoring a burner, observing refractory walls or following the flow of a material.

It’s this fine-tuned, personalized approach that enables us to effectively support our customers in all demanding industrial sectors, guaranteeing impeccable image quality… even where the human eye can’t go.